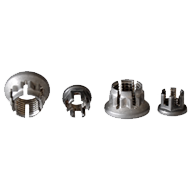

Fastener Grinding

Centerless, Micro, and ECG Grinding Machines for Fasteners

Our Fastener Cutoff and Grinding equipment have helped countless manufacturers to increase production efficiencies and meet the demand for fasteners used in the automotive, aerospace, and countless other industries.

The Tridex line of Precision Abrasive Cutoff Machines provide the ability to cut multiple bars per cycle with a smooth surface finish.

Glebar Centerless Grinders can be integrated with automatic feeding systems, precisely grinding multiple parts per cycle, equating to millions of parts per year. For higher tolerances, Glebar can integrate in-line gauges that provide constant feedback to the grinder and make automatic adjustments, minimizing scrap.

SG-1645

The Tridex SG-1645 Burr-Free Electrochemical NC/CNC Surface Grinder is a faster alternative to traditional surface grinding.

SG-2060

The Tridex SG-2060 Burr-Free Electrochemical CNC Surface Grinder is a faster alternative to traditional surface grinding.

GT-610

The GT-610 Automated Infeed/Thrufeed Centerless Grinding Machine can be custom fitted with automation. This system is the ideal option for when infeed applications do not require a CNC dresser and for the vast majority of thrufeed applications.

CS1-A

The Tridex CS1-A Precision Abrasive Cutoff Machine provides fast, clean cuts with little to no burrs.

P4K

The Glebar P4K Gauging System is the world’s fastest and most accurate profi le metrology system available for long parts or multiple short parts. It is the industry standard for measuring medical guidewires.

GT-610 CNC

Found at the highest end of the GT‐610 series spectrum, the GT‐610 CNC High Precision Automated Infeed/Thrufeed Centerless Grinding Machine excels at grinding a wide range of materials and is the complete “lights‐out” solution for applications where a high degree of automation, data gathering and gauging feedback is required.