Assembly Line Automation

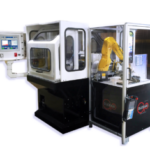

Maximize Efficiency with Turnkey Automation

Glebar’s dedicated staff of engineers and applications personnel can design and integrate a turnkey automated precision grinding solution to meet your specific application needs for your Glebar centerless, micro, double disc, form or OD grinder. We can also address your standalone machine tool automation projects. We provide the unique complement of world class grinding solutions and automation capability to design fully integrated cells for companies around the globe. Our experience in motion controls, robotics and vision and laser measurement systems integration provides a one stop shop solution.

Material Handling:

- SCARA robots

- Six-Axis Robots

- Vibratory Bowls and Conveyors

- Multi-axis actuators

- Pick-and-place

- Custom part feeders designed around your part for high volume production

- Ball feeding

- Wire and tube feeding

- Cleaning and Drying

Measurement & Interface:

- In-process measurement interfaced to machines for automatic size compensation

- Laser gauge diameter measuring devices, both on and off line

- LVDT-based measurement systems

- Profile measurement systems for shaped cylindrical components such as wires and tubing

- Sorting and part accumulation systems

- Palletizing

- Part simulation and staging for post-grinding processing

- Advanced software and controls allow for extreme flexibility

- Eddy Current System

- Interface between machine tools and peripheral components

- Integrate one machine line onto another to maximize production flow