Tube & Wire Cutting Machine Solutions

SYNEO’s Accu-Cut machines target tight-tolerance flexible tubing and wire cutting applications, including soft, brittle and braided and non-braided material such as silicone, PEEK, nylon, polytetrafluoroethylene (PTFE) and Pebax®, stainless steel and nitinol wire.

Accu-Cut machine solutions use quick-change production tooling and advanced cutting techniques to accurately cut tubing to programmable lengths. Accu-Cut machines ensure a perfect square cut, free from burrs, on the proximal and distal end of the tube.

Accu-Cut machines have been designed with the operator in mind, offering precision length and height measurement tools, guided part loading, and a programmable HMI interface with LCD touchscreen as standard features across the product family, while fully bio-compatible and non-shedding part path.

SYNEO’s automated tube and wire cutting machines are designed for optionality to enhance functionality and application breadth, including recipe programming, automatic scrap sorting, and end-slit capabilities.

SYNEO’s Accu-Cut tube and wire processing equipment integrates seamlessly with SYNEO’s Accu-Feed and Accu-Bin products, allowing for upstream feeding and downstream, directional pass-fail binning and sorting processes.

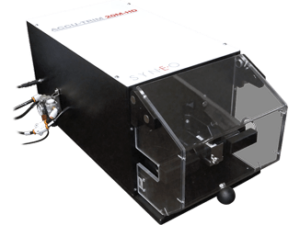

Accu-Cut 202L

Highly regarded among medical device manufacturers for its precision, speed, and adaptability, the Accu-Cut 202L Automated Tube Cutter is known for its clean, square corners and precise lengths with convenient output.

Accu-Cut 202W

The SYNEO Accu-Cut 202W automated wire cutter is a high precision automated medical wire cutter that provides the cleanest cuts for Stainless Steel, Nitinol, and Titanium wire, flat wire, and coils. The automatic guidewire cutting machine offers many state-of-the-art options for recipe set-up, enhanced control, clean and convenient storage.

Accu-Cut 700L

The Accu-Cut 700L Automated Braided Tubing Cutter brings the engineering of the Accu-Cut 202L to difficult materials, including braid-reinforced tubing, stainless steel, polycarbonate and nylon 12.

Accu-Cut 700M

The Semi-Automatic Braided Tubing Cutter targets rotary cutting applications for polyimide and pebax-based stainless-steel reinforced tubing, hard plastics including PEEK and polycarbonate and high durometer Nylon 12, and thin wall 303-4 stainless steel tubing.

Accu-Cut CT & CTXL

The Accu-Cut CT Automated Large Tubing Cutter, based on the Accu-Cut 202L, is designed for applications that demand high traction and high power indexing.

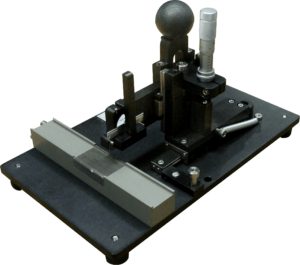

Accu-Cut 20M & 20MHD

The Manual Medical Tubing Cutters trim rough-cut assemblies to precise lengths with square, burr-free cuts.

Accu-Cut 70M

The Manual Medical Tubing Roll Cutter trims rough-cut braided tubing to precise lengths with square, burr-free cuts.

Accu-Cut 70M

The Manual Medical Tubing Roll Cutter trims rough-cut braided tubing to precise lengths with square, burr-free cuts.