Centerless Grinding Machines

From manual to fully automated, our modular GT-610 Series of precision Infeed/Thrufeed Centerless Grinders are able to remove more material faster, and with better surface finishes, than competing machines. Applications for machines within this series include aerospace fasteners, automotive transmission components, engine parts and valve stems, PCD drill bits, arthroscopic bone shavers, bone drill blanks, medical device components and more.

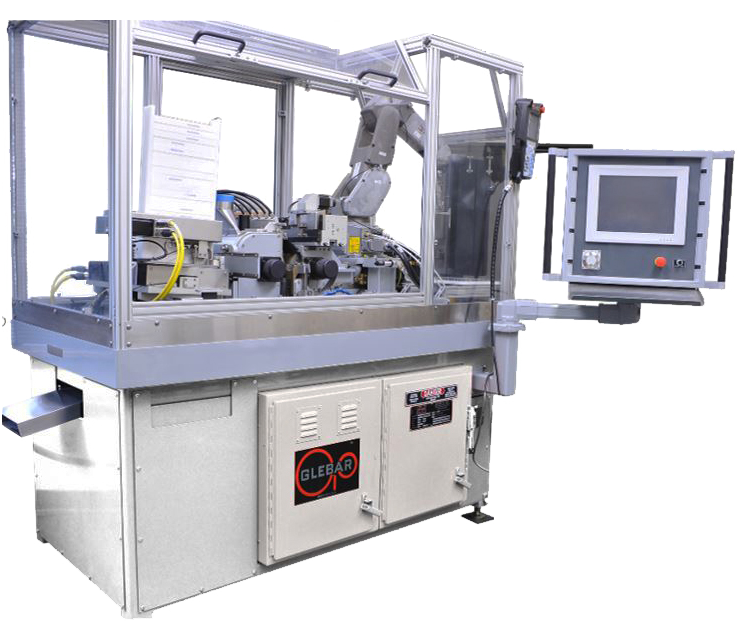

GT-610 CNC

The Glebar GT-610 CNC Infeed / Throughfeed Precision Centerless Grinder is the complete “lights-out” solution for applications where a high degree of automation, data gathering, and gauging feedback is required.

GT-610

The GT-610 Automated Infeed/Thrufeed Centerless Grinding Machine can be custom fitted with automation. This system is the ideal option for when infeed applications do not require a CNC dresser and for the vast majority of thrufeed applications.

GT-610 SD

The GT-610-SD is a highly automated infeed/thrufeed multiple pass machine with a cleaning station, inline gauging and automatic size compensation, designed for use on hard materials.

GT-610M

The GT-610M is an affordable, compact, precision thrufeed grinding system, built for the machine shop. Applications include spool valves, bar stock, pins, bushings, metals, hard and green ceramics, and other engineered materials.