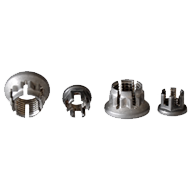

Castle Nuts, also referred to as Castellated Nuts, are used for applications in aerospace and automotive markets where the nut cannot loosen. A cotter pin or safety wire is inserted through a cross-drilled bolt extending through the opposing slots to mechanically prevent the nut from loosening. Without the Castle Nut, the nut would separate from its shaft potentially leading to catastrophic results.

Current Process

Slotting Saws, Abrasive Grinders, Wire EDM, and Sinker EDM are popular mechanical and abrasive processes used for slotting Castle Nuts. The slotting operation requires three cuts per part, cutting two slots per pass. Parts are loaded manually.

Challenge

Typical saws and grinding processes require frequent wheel dressing or saw changing, dramatically reducing productivity and throughput. Current manufacturing processes can distort the slot, damage the thread, or deform the thread. Secondary deburring or re-tapping is often required after slotting. This results in increased scrap rates, increased cycle times, and reduced throughput.

Solution

Solution: Form the slots on Castellated Nuts using our SG series Burr-Free Electrochemical Grinder (ECG) to reduce scrap rates caused by conventional manufacturing processes, improve cycle times, and increase daily throughput.

ECG provides fast, accurate, and burr-free results with no debris after rinsing, no metallurgical damage, and no distortion. Burr-free grind eliminates the need for deburring or other secondary operations improving productivity and reducing scrap. An optional pallet index table allows full production without stopping to load and unload parts. For very high-volume parts, a custom dial index ECG machine can be built with three ECG spindles, so every cycle produces a finished part.

In a recent test, the SG-1645 was used to grind 0.165″ slots into Castle Nuts. The grind resulted in a cycle time of 8.9 seconds, equating to 339 parts per hour, generating as much as a 70% savings in productivity.

Excellent wheel life, requiring minimal wheel truing and dressing, helps to maintain a high-quality grind without increasing cycle times.

Explore | SG-1645 Burr Free ECG Surface Grinder

SG-1645

The SG-1645 Burr Free Electrochemical NC/CNC Surface Grinder from Tridex Technology provides burr free and low force cutting leaving no heat affected zones while cutting.