Challenge: The customer wants to decrease cycle time while maintaining tight concentricity specifications for roughing a tungsten carbide pin.

Solution

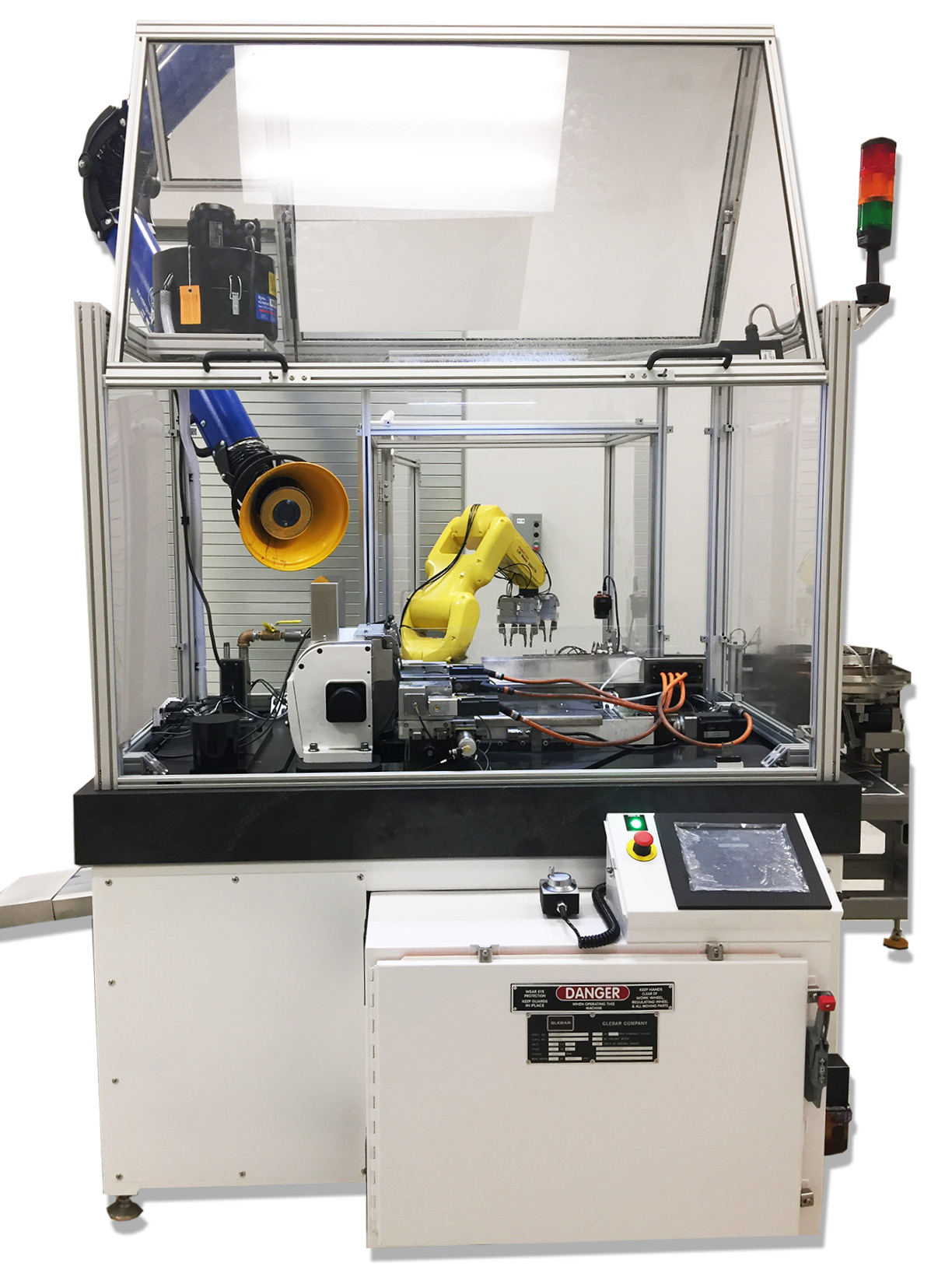

The Glebar PG-9DOD addressed the challenge. The system was configured with dual fixtures, a six-axis robot and bowl feeder – decreasing cycle time by 50% by grinding two parts at a time with dual fixtures. This machine excels at grinding small diameter components which require a tight concentricity specification.

- Parts are fed onto a smart conveyor from the bowl feeder.

- The conveyor orients and spaces the parts.

- Cameras identify imperfections. Bad parts are rejected prior to grinding.

- OD machines normally process one component per cycle.

- We are processing two components per cycle.

- The machine also includes a safety enclosure and recycling coolant filtration system.

RELATED: See the GT-610 Carbide Finishing Case Study

• Part handling is minimized by holding four parts at a time – two raw and two ground.

• Two fixtures OD grind simultaneously — decreasing cycle time by 50%

• Built on a granite base for optimal stability and precision control.

Explore | PG-9DOD OD Grinding Machines

PG-9DOD

The PG-9DOD OD Grinding System produces components requiring a tight concentricity specification. Examples include bearings, bushings, and engine components.