Challenge: To process carbide and polycrystalline diamond with complete automation, conserving grinding wheels and using little power, all on a machine within a small footprint

Solution

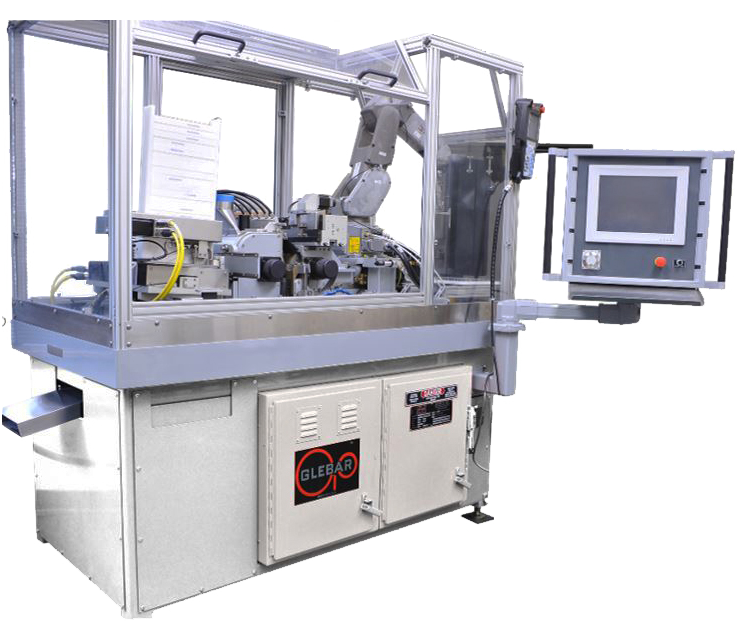

Glebar’s GT-610-SD uses machine intelligence and data to predict and preempt the machine’s operational parameters. The machine is a fully automatic system and is a fraction of the cost and size of any competitors’ models. A standard employee can operate the machine, with minimal training, to its optimum capability. The production and efficiency of the machine is second to none. Glebar has the manufacturing capability to mass produce the machine to outfit any carbide or PCD manufacturer’s operation in an expeditious manner.

Explore | GT-610 SD Infeed/Thrufeed Centerless Grinding Machines

GT-610 SD

The GT-610-SD is a highly automated infeed/thrufeed multiple pass machine with a cleaning station, inline gauging and automatic size compensation, designed for use on hard materials. This machine is ideal when a high degree of data gathering is required along with a desire to limit consumable usage. Applications include PCD drill bits and hard carbide components for drilling industries. It is available with enclosure (as shown).