Current process:

Legacy equipment did not meet current CE standards. The brittle shafts break in the grinder’s feeder increasing scrap rates.

Challenges:

Deliver an automated, turnkey process that can integrate with the customer’s existing isostatic press to accuractely handle and grind the parts. The process had to ensure the ceramic shafts would not chip or break due to the brittle consistency of pre-sintered ceramics.

Solution

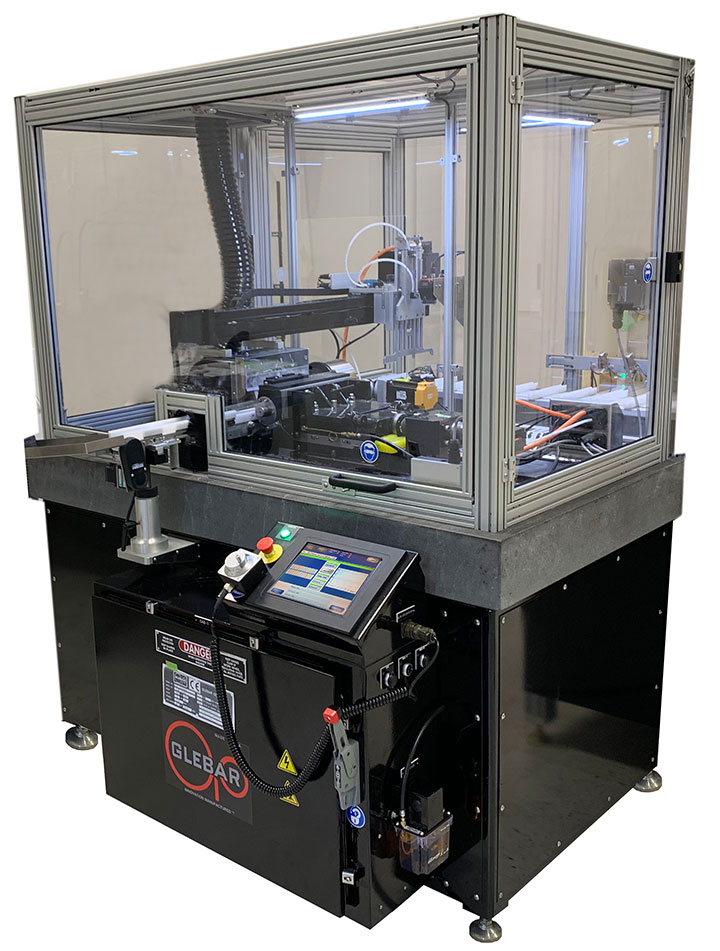

Solution: PG-9DHD Centerless Form Grinder

In this application, the PG-9DHD Centerless Form Grinder is fully automated with a six-axis robot, inspection camera station, cleated conveyor, and gantry to reduce scrap rates and improve OEE. Maintains a tolerance of +/- 0.001″, removing 0.040″ (0.020″ per side) of stock material. Grinds two ceramic shafts every six seconds, allowing it to keep up with the ceramic press.

The six-axis robot senses and transfers six ceramic shafts at a time from the press onto a cleated conveyor.

Prior to grinding, the ceramic shafts pass through a camera station to ensure the shafts are free of defects.

The gantry head feeds and removes two ceramic shafts at a time from the grinding area maximizing OEE.

This PG-9DHD was CE Certified and featured an enclosed robot station and grinding area for operator safety.

Typical Glebar installations have one operator running three or more machines because of the reliability of the automation and grinder performance.

Glebar machines can grind most hard to turn materials such as carbon fiber, fiberglass (including G10), Teflon, Santoprene, and polypropylene.

Explore | PG-9DHD Form Grinding Machines

PG-9DHD

The PG-9DHD Centerless Form Grinder produces multiple parts from a single piece of material, in addition to grinding pre-formed parts to finished shape with extreme precision. Examples of applications are carbon fiber components, fuse bodies, golf balls, drumsticks, felt pen nibs, check valves for pumps and valves, and insulators for electronic components.