PCB Assembly Manufacturing Solutions

SYNEO Accu-Press connector pressing machines are commonly used in the printed circuit board (PCB) assembly processes to press singular connectors, integrated housings, or modules featuring Press-Fit connector technology. Trusted by the largest manufacturers of printed circuit board assemblies for their most demanding applications, SYNEO brings industry-leading connector press technology to solve your next challenge.

What is Press-Fit Technology?

Press-Fit is a connector technology that manufacturers use to create highly reliable electro-mechanical interconnects without the use of solder.

Press-Fit technology is used to manufacture electronic and electro-mechanical components for a wide range of industries, from data and communication to transportation and mechanics.

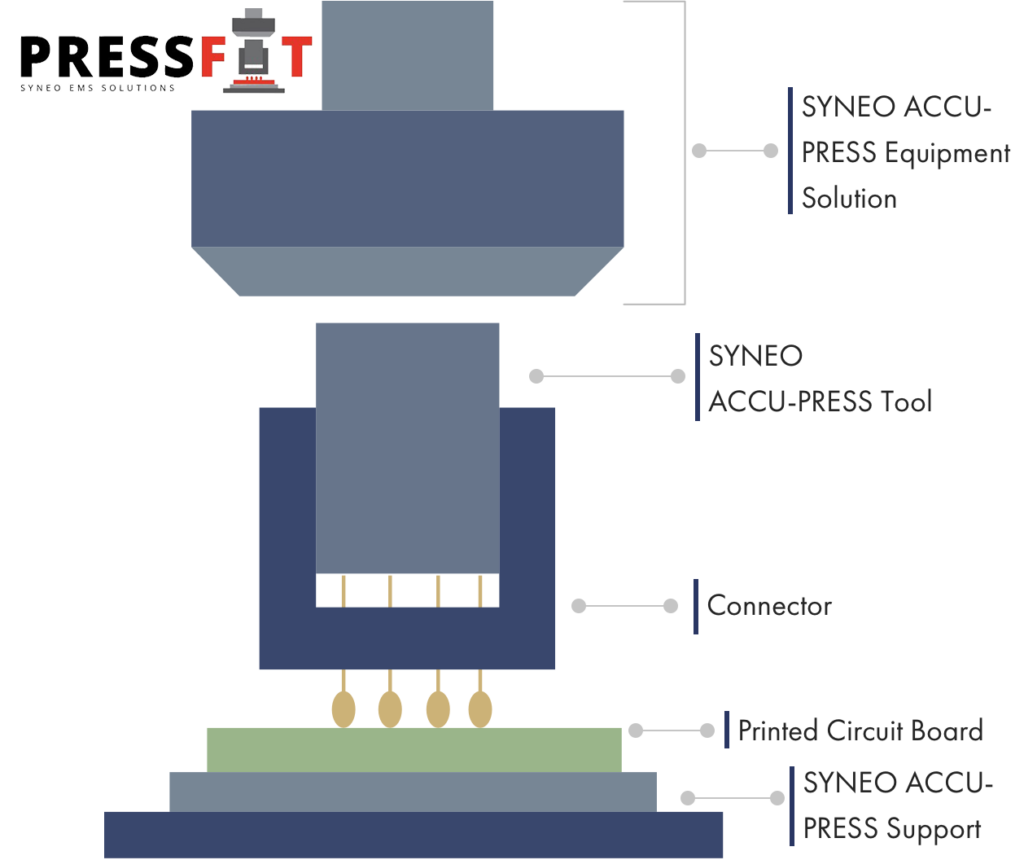

The standard press-in process utilizing press-fit connectors utilizes the following assembly components and tools:

- Printed circuit board

- Press-Fit connector

- Press-Fit tool with press action on the individual contacts

- PCB support tool

- Press-in equipment with the capability to distribute the total force required by the Press-Fit connector

Why SYNEO

Trusted by the largest manufacturers of printed circuit board assemblies for their most demanding applications, let SYNEO bring industry-leading connector press technology to solve your next challenge.

- SYNEO is the Originator, Cultivator, and Innovator of Connector Press Equipment Technology

- SYNEO’s Press-fit solutions are designed to be the most advanced, intuitive, user-friendly equipment option available

- SYNEO’s Press-fit equipment is customized to customer-specific applications

Using SYNEO’s proven S3 Sales & Application review process, we guarantee results for our customers.

Customer Focused

SYNEO is the innovator of the Compliant Pin Connector Servo-Electric Press-Fit machine. With almost 30 years of Press-Fit application experience, SYNEO’s experts serve as the foundation for connector pressing automation. SYNEO understands our customer’s needs and has designed machines that generate the highest levels of force-feedback, are able to have the highest precision over the full-scale force range, and are easy to program for our customers, while also eliminating waste and enhancing quality.

Developed to tackle the most challenging pressing applications, SYNEO’s presses focus on minimizing operational pain-points that manufacturers experience when pressing connectors. Below are a few examples of those key pain-points:

- Yield-loss from damaging of a populated printed circuit board assembly due to bent pins

- Excess operating costs associated slow thru-put tied to manual connector press tool changes and manual placement requirements

- Increased operator burden or machine down-time associated with time loss associated with change overs in high-mix environments.