Centerless, Micro, & Electrochemical Grinding and Cutoff Machines

Precision Grinding Solutions

Total Guidewire Solutions

About Glebar

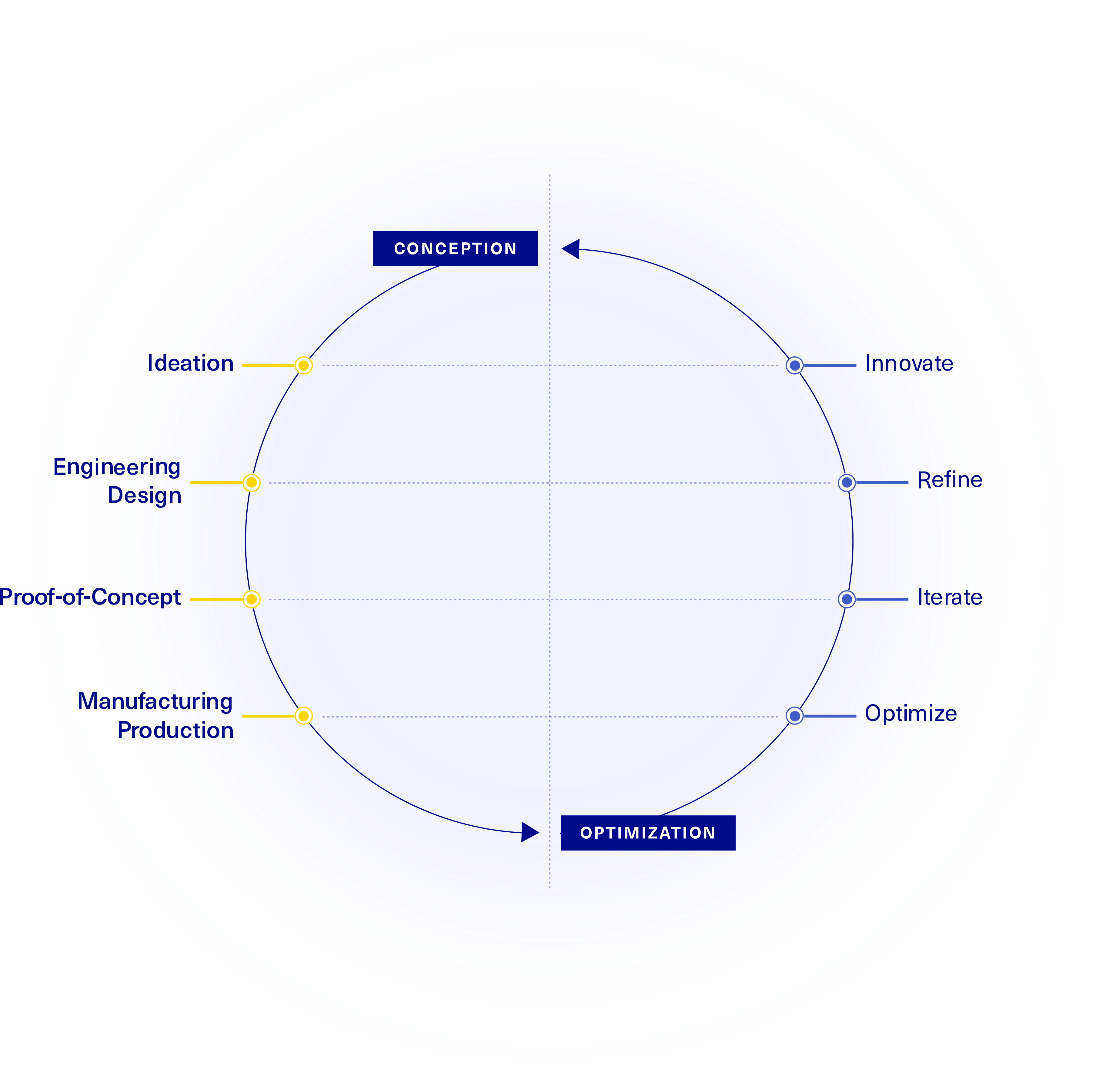

Glebar partners with its customers to achieve a complete solution that focuses on continuous improvement and ROI. Glebar’s machines are well represented across all industries around the globe manufacturing grinding solutions such as double disc grinders, form grinders, OD grinders, micro grinders, gauging systems, burr free ECG cutoff and grinding machines, and infeed/thrufeed centerless grinders. Our machines are known for their precision, longevity, flexibility, and efficiency.

Precision Grinding Solutions

A global leader in micro centerless, electrochemical and precision abrasive cutoff and grinding since 1952, Glebar works with customers to design and implement state-of-the-art grinding solutions that improve efficiency and repeatability while maintaining the highest level of quality.