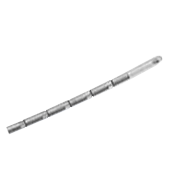

TF-9D: Infeed/Thrufeed Centerless Grinder

The Glebar TF-9D Infeed/Throughfeed Centerless Grinder uses computer controls to grind both hard and soft materials including catheters, medical guidewires, and spinal cord stimulators. Inside the compact footprint is a 7HP main spindle motor powering an 8.625” wide work wheel combining to remove more material faster, and with better surface finishes, than similar machines with narrower grinding wheels. The TF-9D is designed to enhance productivity through a simple control interface and automation integration. Common applications include guidewires, catheter bodies, spinal cord stimulators, pins, and other engineered materials.

Key Features

- Grinds both hard and soft materials.

- Intuitive touch screen HMI allows an unskilled operator to run multiple high-precision machines simultaneously.

- Closed-loop control via a linear scale on the movable slide.

- Interface to measurement instruments allows for automatic size compensation.

- Independent upper and lower slide positioning.

- A single operator can change the work wheel in less than 15 minutes.

- Automatic infeed for forming small shaped parts.

- Remote connectivity simplifies troubleshooting and maintenance.

- Built-in infeed and throughfeed cycles with programmable inputs and positioning.

- Available stationery and removable wheel dressers.

- Full turnkey automation integration is available including feeders, robots, pick/place gantry, gauging, cleaning, and sorting assemblies.

- Glebar P4K Gauging System is available to feed diameter measurements to the control system for automatic size compensation.

Specifications

- Diameter Accuracy: 0.00005” (1.3 μm)

- Roundness: 0.00005” (1.3 μm)

- Grinding Diameter Capacity: Min 0.002” (0.05mm) – Max 2.5” (63.5mm)

- Grinding Length: Infeed 8” (200mm), Thrufeed – no limit

- Work Wheel Power: 7.5HP (5.6kW), 10HP (7.5kW), 15HP (11kW)

- Work Wheel Diameter: 9” (229mm)

- Work Wheel Width: 8.625” (219mm)

- Work Wheel RPM: 2,400

- Regulating Wheel Diameter: 4” (100mm)

- Regulating Wheel RPM: 10-400

- Machine Footprint: 58” x 31” x 71” (147 x 79 x 180cm)

- Machine Weight: 2,085 lbs (with granite bed)

- Resolution: 0.1μm (0.000004”)

- Power: 480VAC, 60Hz, 40A (15HP), 25A (7.5HP)

- Air: 4CFM @ 80PSI

- Machine Bed: 6” Thick Granite (also available on cast iron)