GT-9AC: Automated Guidewire Grinder

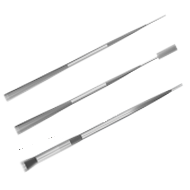

The Glebar GT-9AC Automated Guidewire Grinder excels at precision grinding of medical guidewires with multiple tapers, paddles, and parabolic shapes with speeds as fast as a centerless grinder. Instead of using sensors to detect the wire position and trigger diameter changes, high-speed imaging technology and a 1-micron encoder run the entire length of the feeder providing constant updates displayed on the touchscreen HMI allowing for quick, simple adjustments. The result is crisp, clear tapers and virtually no limit to the number of tapers, paddles, and parabolic shapes that can be ground.

Key Features

- Available variable frequency drive on the work wheel spindle increases wheel surface feet when running super abrasives such as vitrified CBN.

- Easily holds tighter tolerances required by today’s guidewires.

- Change wire length or profile in seconds.

- Spindle RPM can be varied depending on the wheel type and wheeldressing parameters.

- Automatic wheel balancing and acoustic emissions system.

- Automatic blade sizing makes grinds easy and repeatable.

- Servo-driven, variable speed regulating wheel drive.

- Work rest blade holder with built-in ramp for simple height adjustment.

- Grind lengths are not dependent on wire cut length.

- Remote connectivity simplifies troubleshooting and maintenance.

- Programmable work wheel dresser.

- Available Extractor allows for double-ended grinds or grinding multiple parts in the same cycle.

- High-speed imaging technology and a 1-micron encoder run the length of the feeder.

- Wire position is updated every 0.00025” (0.006 mm) at typical grinding speeds.

- Software interface allows an unskilled operator to run multiple high-precision machines simultaneously.

Specifications

- Diameter Resolution: .00005”

- Grinding Diameter Capacity: .045”

- Work Wheel Diameter: 9” (230mm)

- Work Wheel Power: 2HP

- Work Wheel RPM: 2,500

- Regulating Wheel Diameter: 4” (100mm)

- Upper Slide Resolution: 0.1μm (0.000004”)

- Lower Slide Resolution: 0.1μm (0.000004”)

- Machine Footprint: 58” x 31” 71” (147 x 79 x 180cm)

- Machine Weight: 3,520lbs

- Maximum Wire Length: 16 feet

- Minimum Wire Diameter: 0.0015”

- Maximum Wire Diameter: 0.045”

- Grinding Length: 15 feet

- Feeder Length Resolution: 1μm (0.00004”)

- Tooling: 1.5” (38mm) and 3” (76mm) wide tooling.

- Feeder Lengths: 6’ (180cm), 12.5’ (380cm), 16’ (500cm)

- Power: 480VAC, 60Hz, 20A

- Air: 4CFM @ 80PSI

- Machine Bed: 6” Thick Granite