Electrolyte Tank Management System

At Glebar, we are committed to providing state-of-the-art applications and solutions, which means we are always engaged in process development procedures to ensure our equipment meets our customers’ expectations.

For example, our customers wanted an easier, more reliable way to check the electrolyte levels of their Tridex ECG Cutoff & Grinding machines without having to engage in the tedious and less accurate manual process. To achieve this, our team developed an enhanced electrolyte tank featuring digital ultrasonic sensors that connect with an I/O link to the HMI screen enabling better grind management, improved grind efficiency, and reduced downtime.

Challenge

Operators use float hydrometers to measure the electrolyte’s salt density and perform visual inspections of the clean and dirty electrolyte fill levels.

These tests:

- are manual and operator-dependent processes.

- provide insufficient data to accurately plan for electrolyte change.

- reduce the quality of the grind increasing scrap rates.

- result in lower process capability.

Solution:

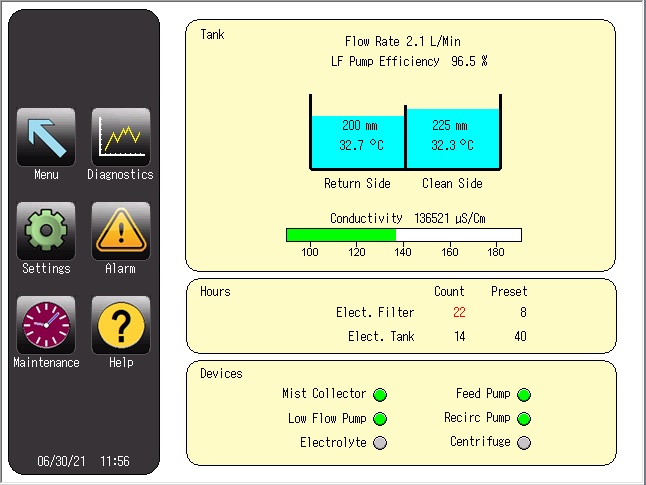

Upgrading to the new Electrolyte Tank Management System provides customers with a new electrolyte tank featuring digital ultrasonic sensors that connect with an I/O link generating a graphical and numeric display of electrolyte health and fill levels on the HMI screen.

Benefits: Real-time Information Display Improves Grind Quality, Increasing Uptime

Using the HMI, operators can monitor electrolyte temperature and conductivity, and the fill levels of the clean and return electrolyte.

This allows customers to:

- monitor Precision Flow Pump efficiency to plan for preventive maintenance.

- reduce time spent troubleshooting; the HMI alerts operators to changes in electrolyte efficacy.

- allow operators to precisely adjust the electrolyte flow rate through the HMI to provide a better, cleaner, and more consistent grind.

- make precise adjustments through a simpler and more accurate process.

- virtually eliminate unplanned downtime increasing thruput.

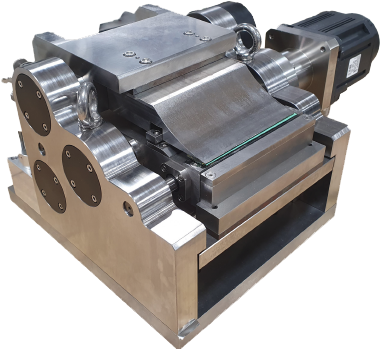

Upgradeable Machines

CS1-E

Cutoff, Precision Abrasive and ECG

The CS1-E Burr Free Electrochemical (ECG) Cutoff machine from Tridex Technology features completely burr-free cutting and very low cutting forces ideal for tubing and heat-sensitive alloys. It cuts at low…

Learn More

Request A Quote

CS1-EA

Cutoff, Precision Abrasive and ECG

The CS1-EA from Tridex Technology combines the best of the CS1-A Precision Abrasive and CS1-E Electrochemical Cutoff machines into one robust and compact design. Visit the Tridex Technology YouTube Channel…

SG-1645

Burr Free ECG Surface Grinder

The SG-1645 is our smaller (6″ x 18″) electrochemical surface grinding machine. It features a stationary table and optional rotary table to fit your production needs. It provides burr-free and…

SG-2060

Burr Free ECG Surface Grinder

The SG-2060 Burr Free Electrochemical CNC Surface Grinder from Tridex Technology is our largest electrochemical surface grinding machine. It features a stationary table and optional rotary table to fit your…

PGS-100

Burr Free ECG Point Grinding

The PGS-100 is a fully programmable pointing and material handling system to manufacture a wide variety of medical device points on tubing or solid wire, such as medical needles or…